Description

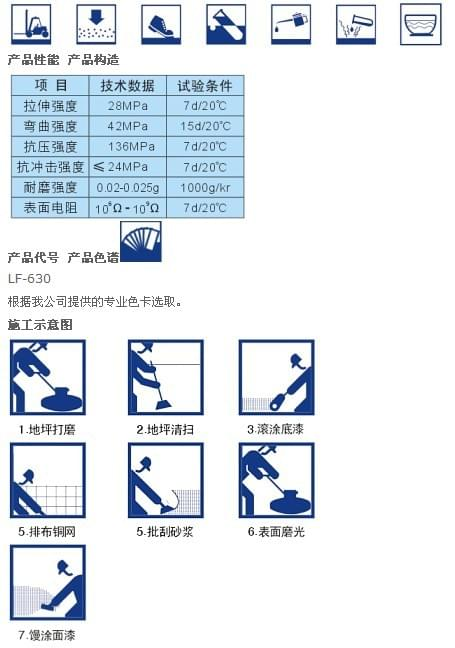

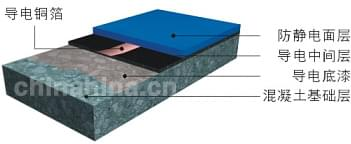

Antistatic floor material is a special new material mixed with conductive filler in epoxy resin. Before the coating curing, the substrate and conductive filler exist independently of each other, are discontinuous, and are in an insulating state; after the coating curing and drying, the solvent volatilize, the substrate resin and conductive filler are mixed and cured, closely connected with each other, to produce conductivity. The conductive copper network is laid in the floor structure to further enhance the electrostatic dredging function of the floor. Anti-static coating is applied in the production workshop floor and wall, used for the electrical conductivity of the coating, forming an electrostatic leakage channel, thus inhibiting the accumulation of static charge phenomenon, to achieve the effect of anti-static coating. Product use range product characteristics applied to some high requirements, strict overall packaging of electronics, microelectronics, communication, computers, precision instruments, petrochemical and other industries all need to anti-static places, coating in the floor and wall and other surface areas. Apply electrical conductivity: release static electricity to prevent static electricity generated by friction. Low resistivity: the resistance value is in the semiconductor range below 108 Ω. Conductivity: The conductive coating forms a seamless color floor. Hard corrosion: durable, hard resistant coating film to prevent corrosion.